1. Find a suitable place

Seize the basic three elements: unobstructed fresh air, power supply in line with the unit, and circulation flow in line with the unit. Inverter pool heat pump units should be installed in outdoor ventilated and easy to maintain places, not in narrow airless spaces; at the same time, the unit should be kept at a certain distance from the surroundings to keep the air flowing smoothly, and no debris should be stacked in the position of the inlet and outlet of the unit to avoid reducing the heating efficiency of the unit.

2. Prepare the basic elements

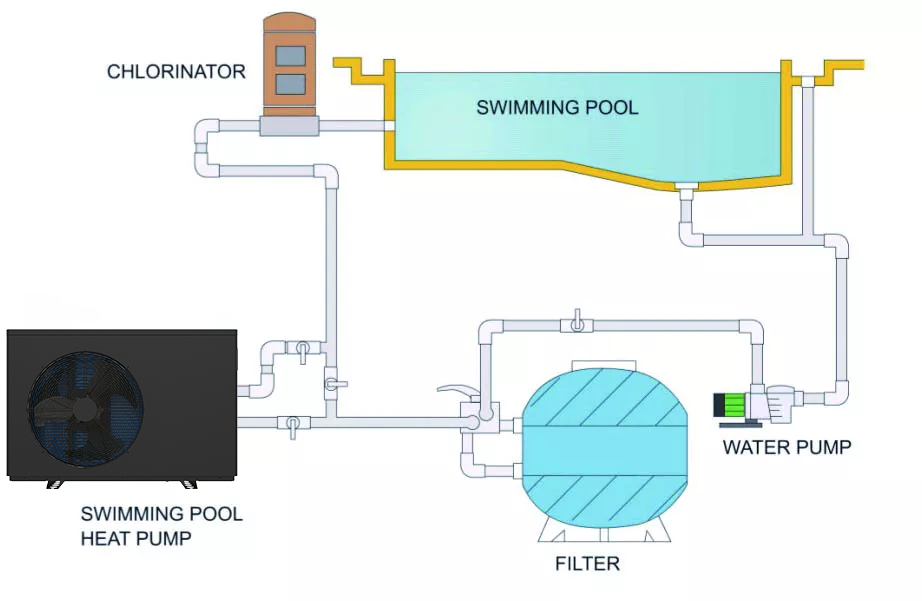

Swimming Pool \ Chlorination \ Circulation \ Water Pump \ Sand Filter \ Inverter Pool Heat Pump

3. Notes on the connection process

1)Install the air source heat pump pool unit downstream of all filtration units and pool pumps, and upstream of all chlorine generators, ozone generators, and chemical disinfection. The inlet and outlet pipes can be made directly from PVC pipes;

2) Normally, the air source heat pump pool unit should be installed within 7.5 metres from the pool, and it is recommended to pack 10mm thick insulation pipes if the pool water pipes are too long to avoid excessive heat loss from the unit and resulting in insufficient heat production;

3) The waterway system should be designed to install a live connection or flange on the inlet and outlet of the heat pump to facilitate drainage in winter and to be used as an access port during maintenance;

4) Shorten the water pipeline as much as possible, avoid or reduce unnecessary pipeline changes to reduce resistance losses, and install an exhaust pipe at the highest position of the water main pipeline to facilitate timely evacuation when there is gas in the water pipeline; install a water release valve at the lowest point of the system to facilitate water release when cleaning the system.

5) The water system must be equipped with a pump of suitable flow and head to ensure that the water flow meets the requirements of the unit. The water pump should be connected to the unit and the water system pipeline by anti-vibration flexible joints, and should also set up its own bracket to avoid stress on the unit.

6) The water side of the heat exchanger is designed to withstand a water pressure of 0.4 Mpa. To prevent damage to the heat exchanger, it must not be used at excessive pressure.

7)During the operation of the heat pump, the air temperature will be lowered by about 5 degrees and condensation will be generated on the evaporator fins and will fall onto the chassis and be discharged through the plastic drainage nozzle installed on the chassis, which is a normal phenomenon (condensation is easily mistaken for water leakage in the heat pump water system), and a drainage pipe must be installed to discharge the condensation in time.

8)Do not connect the tap water pipe or other water pipes to the circulation pipe, so as not to cause damage to the circulation pipe and the heat pump unit.

9)The water tank of the hot water heating system needs to have good insulation performance, please do not install the water tank in a place where there is pollution and corrosive gas.

4. Requirements for the power supply.

1) The socket must be reliably grounded and the capacity of the power socket should meet the current power requirements of the main unit.

2) Do not place other electrical equipment around the power socket of the unit to avoid tripping of the leakage protection plug.

3) Install the water temperature sensor probe into the probe tube in the middle of the water tank and fix it.

5. Aftercare and maintenance

Inverter pool heat pumps are highly automated equipment, and the reliability and service life of the unit will be unexpectedly improved if the unit is regularly checked for condition and if long-term and effective maintenance and servicing is carried out.