The R410A EVI On Off Commercial Heating Heat Pump for Commercial Building Heating uses the lower GWP refrigerant R410A and is mainly used in large commercial buildings such as schools, communities, hotels, shopping malls, etc. Indoor heating area is up to 920 m2 or even larger which can be customized. The R410A EVI On Off Commercial Heating Heat Pump for Commercial Building Heating can be customized to meet the needs of cooling, heating and domestic hot water supply.

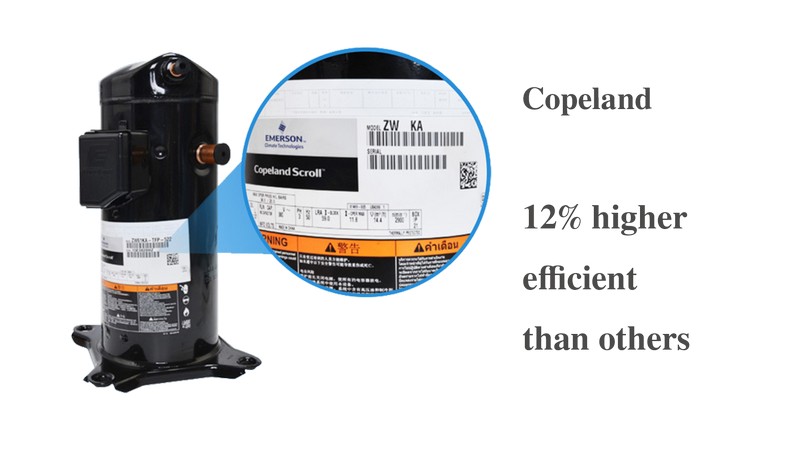

2. Copeland Compressor

The R410A EVI On Off Commercial Heating Heat Pump for Commercial Building Heating uses the famous Emerson brand compressor from the USA – Copeland – which is 12% more efficient than the most common compressors on the market. Under normal conditions, after the compressor has been turned off, the system will turn on again after 3 minutes by default, effectively extending the life of the compressor.

3. Low Noise Fan Blades

The R410A EVI On Off Commercial Heating Heat Pump for Commercial Building Heating is a large commercial unit, but its noise level is still very well controlled. In addition to the use of a fully inverter DC compressor to reduce noise, it uses a fan blade that also has a noise reducing effect.

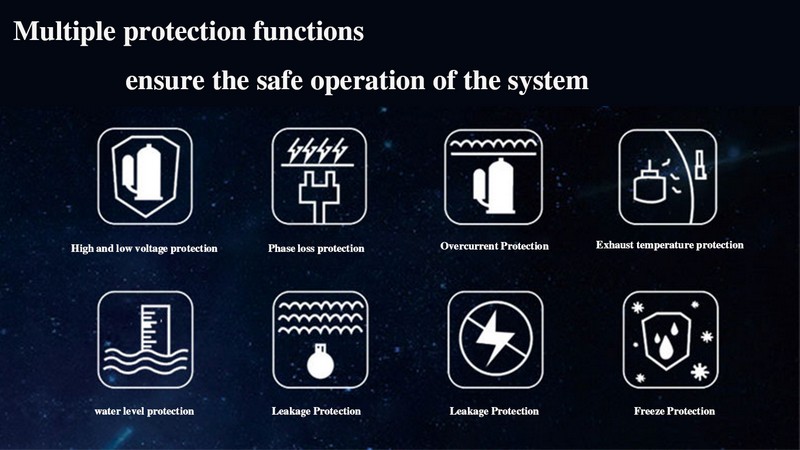

4. Multiple Protection

The R410A EVI On Off Commercial Heating Heat Pump for Commercial Building Heating has multiple protection features such as high and low voltage protection, phase failure protection, overcurrent protection, exhaust temperature protection, water level protection, water flow protection, earth leakage protection and freeze protection to ensure safe and stable system operation.

| R410A EVI On Off Commercial Heating Heat Pump Product Parameters | |||||

| Model No. | NEAHDP-45.9TC/K | NEAHDP-61.5TC/K | NEAHDP-77.9TC/K | NEAHDP-90.2TC/K | |

| <Performance at Air 7℃, Water in/out 40/45℃> | |||||

| Heating Capacity | kW | 45.90 | 61.50 | 77.90 | 90.20 |

| Power Input | kW | 13.62 | 18.03 | 22.97 | 26.60 |

| Rated Current | A | 27.28 | 36.11 | 46.01 | 53.28 |

| C.O.P. | W/W | 3.37 | 3.41 | 3.39 | 3.39 |

| Advised House Area | m2 | 440~460 | 590~620 | 770~790 | 900~920 |

| <Performance at Air -30℃, Water in/out 30/35℃> | |||||

| Heating Capacity | 22.60 | 30.30 | 38.30 | 44.40 | |

| Power Input | 13.31 | 16.29 | 20.76 | 24.04 | |

| Rated Current | – | – | – | – | |

| C.O.P. | 1.84 | 1.86 | 1.85 | 1.85 | |

| Advised House Area | 210~230 | 290~310 | 370~390 | 430~450 | |

| <Performance at Air 35℃, Water in/out 12℃/7℃> | |||||

| Cooling Capacity | kW | 41.77 | 55.97 | 70.89 | 82.08 |

| Power Input | kW | 13.77 | 18.23 | 23.23 | 26.90 |

| Rated Current | A | – | – | – | – |

| E.E.R. | W/W | 3.033 | 3.069 | 3.051 | 3.051 |

| Advised House Area | m2 | 400~420 | 540~560 | 690~710 | 810~830 |

| <System Parameters> | |||||

| Working Temp. | ℃ | -25~45 | |||

| Outlet Water Temp. | ℃ | 55~60 (Heating) / 7~12 (Cooling) | |||

| Power System | V | 380V/50Hz/3Ph | |||

| Control Panel | LCD Display | ||||

| Compressor | Scroll | ||||

| Refrigerant Type | R410A | ||||

| Refrigerant Charge | g | – | – | – | – |

| Condenser | High Efficiency Tank Heat Exchanger | ||||

| Evaporator | Fin Heat Exchanger | ||||

| Throttling Device | EEV | ||||

| Defrost Function | with Intelligent Defrosting | ||||

| Motor Quantity | pcs | 2 | 2 | 2 | 3 |

| Motor Power Input | W | – | – | – | – |

| Motor Speed | rpm | – | – | – | – |

| Fan Direction | Horizontal | ||||

| Water Connection | mm | DN40 | DN50 | DN65 | DN65 |

| Pressure Drop | kPa | ≤78 | ≤80 | ≤85 | ≤88 |

| Advised Water Flow | m³/h | 8.80 | 11.80 | 14.90 | 17.20 |

| Waterproof Grade | IPX4 | ||||

| Electricity Protection | Ⅰ | ||||

| Sound Pressure (10m) | dB (A) | – | – | – | – |

| Sound Pressure (1m) | dB (A) | ≤68 | ≤70 | ≤72 | ≤75 |

| <Package Information> | |||||

| Net Weight | kg | 380 | 485 | 582 | 665 |

| Gross Weight | kg | 400 | 508 | 615 | 730 |

| Net Size (W*D*H) | mm | 1507*857*1611 | 1850*1000*1950 | 2000*1100*2080 | 2200*1100*2080 |

| Package Size (W*D*H) | mm | 1517*867*1741 | 1860*1010*2080 | 2010*1110*2210 | 2010*1110*2210 |

| Loading per 20’GP | pcs | 6 | 6 | 5 | 5 |

| Loading per 40’GP | pcs | 13 | 12 | 10 | 10 |

| Loading per 40’HQ | pcs | 13 | 12 | 10 | 10 |

| *More details please contact us. | |||||

2. After-Sales Service

1) Certificate: CE & ROHS;

2) Warranty: the whole unit for 2 years, the compressor for 5 years, the titanium tube heat exchanger for 7 years; 1% free spare parts for the container order;

3) Support: Provide relevant documentation or video tutorials and real-time technical questions and answers to help customers solve problems quickly.

2. Production Capacity

The NOKKINGHAM factory is largely automated and is capable of producing more than 1000 heat pumps per day, while strict production processes and quality controls ensure timely delivery.

3. Transport Options

NOKKINGHAM has partnered with a number of shipping or courier companies and is able to offer a wide range of integrated transport solutions from door to port, door to door and more.